BizLink Silitherm

One of the Biggest Producer for Silicon Cables

BizLink Silitherm s.r.l. was founded in 1981 in Monticelli D’Ongina (PC), and became one of the biggest producer for silicon cables. Our production site is located 90km southeast of Milano and specialized in the mixing and production of silicone rubber material for cables. Since 2022 it is a proud member of the BizLink Group IN BG, delivering more than 40 years of experience in silicone cable market as competence center for the Business unit Silicone. With an uncounted number of different products and customer specific solutions, BizLink Silitherm is active in different markets and sectors such as Automotive, Renewables & Transportation, Energy and Power control, electrical appliances and safety applications. Today, BizLink Silitherm is well known worldwide as a stable and reliable partner for finding and delivering the right solution for the different markets and supply chains.

Environment & Energy

BizLink Environment & Energy Management

BizLink Silitherm has always had a sustainable business approach and awareness of it‘s environmental responsibility. This can be experienced in all of our production processes, as well as our accountability in the use of ressources. Water recycling, the reduction of emissions during all our processes and the constant progression of sustainable concepts are part of our DNA. For example, for 15 years we are producing a part of our needed energy with PV inhouse, expanding these possibilities constantly where possible.

Process in house:

- Copper drawing and stranding

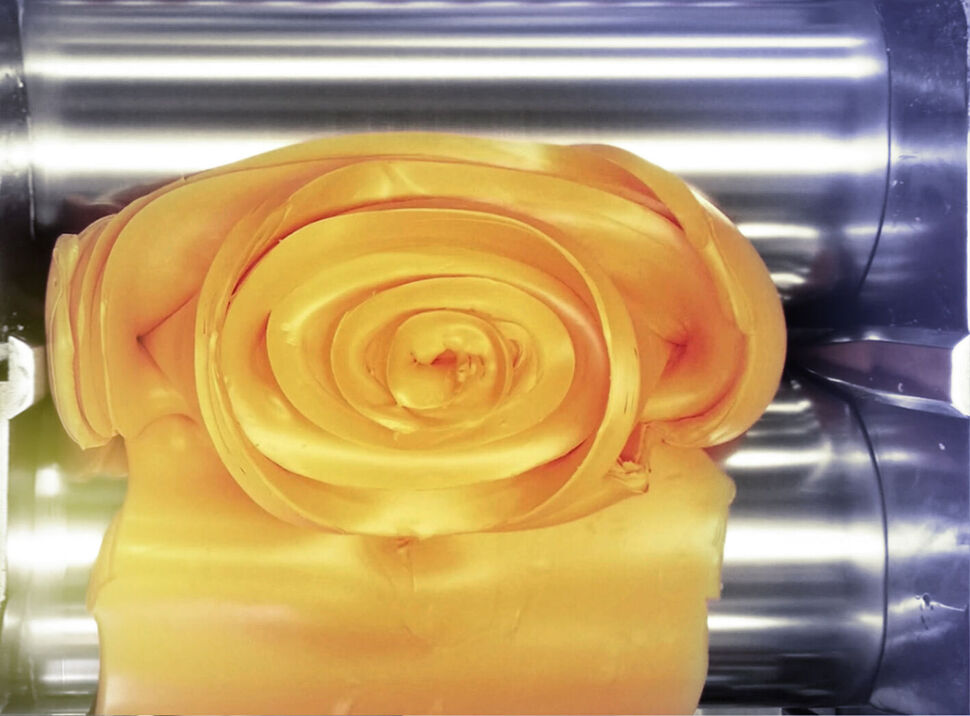

- Silicone rubber compounding

- Silicone extrusion and cross linking

- Twisting of cores

- Shielding / Glassbraiding

- Testing

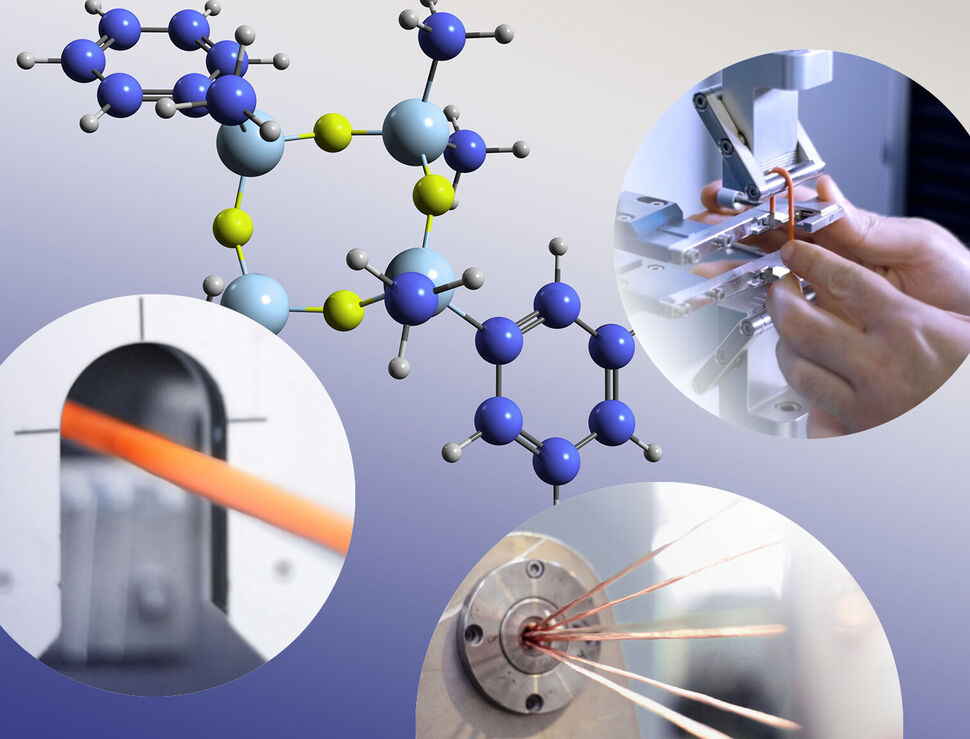

Material

Why Silicone as insulation material?

Silicone offers lots of attractive properties such as:

- Wide temperature range from −60 °C up to +200 °C

- Halogene free material

- Flame retardant material

- Advantage of a 100 % cross linked material

- Low smoke density, corrosivity and toxicity

- Highly flexible cables also under extreme conditions

- Reliable high voltage resistance